Best quality Electrical Drag Chain - TL250 Steel Energy Drag Chain – JINAO

Best quality Electrical Drag Chain - TL250 Steel Energy Drag Chain – JINAO Detail:

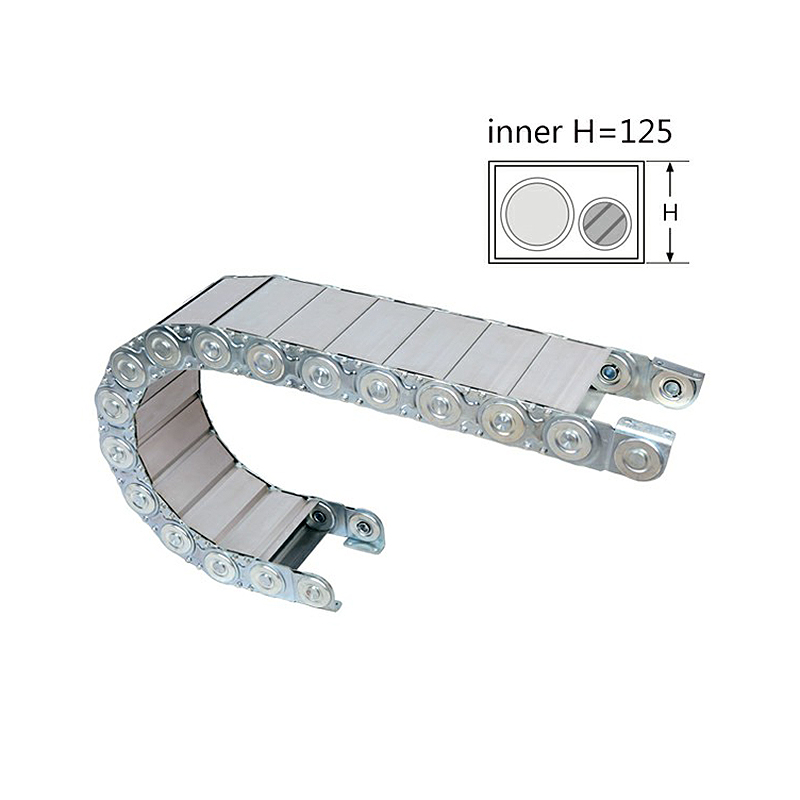

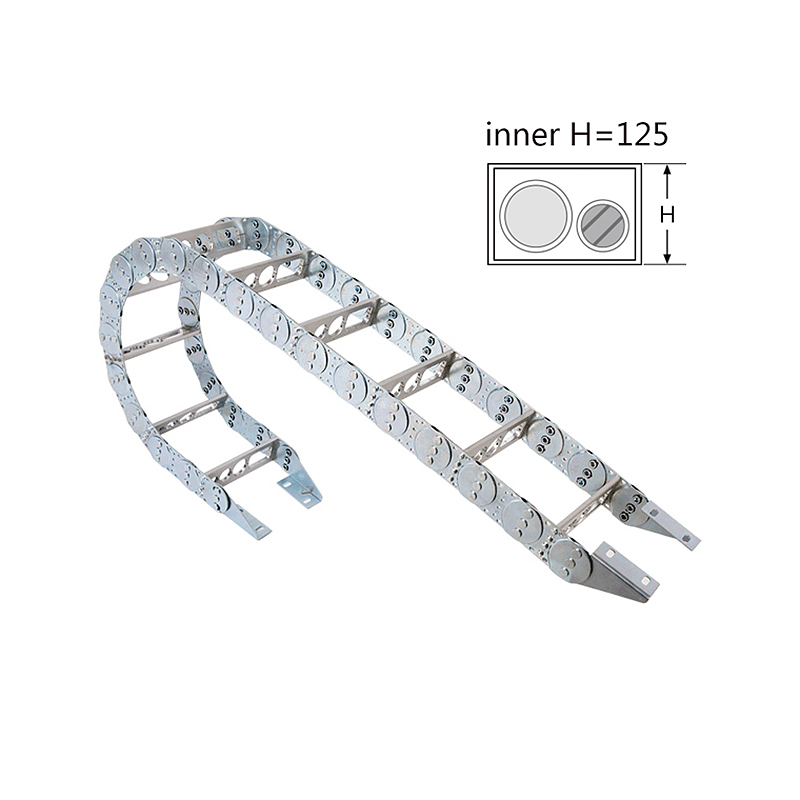

The theme of TL series drag chain is composed of chain plate (high quality steel plate chrome plating), support plate (aluminum alloy), shaft pin (alloy steel) and other parts, so that there is no relative movement or distortion between cable or rubber tube and tow chain. Chain plate after chrome plating treatment effect of the novel appearance, reasonable structure, high strength, rigid ametabolic, easy installation, use and reliable, easy to tear open outfit, especially the product USES the high strength wear resistant materials, alloy steel as the shaft pin, improve the wear resistance strength, bend more flexible, less resistance, reduce the noise, which can guarantee long time use not deformation, not prolapse. Due to its exquisite appearance, this product can greatly enhance the overall artistic aesthetic effect of machine tools and equipment, and enhance the competitiveness of China’s machine tools and mechanical equipment in the international market.

When designing cable chains care needs be taken when selecting firstly the type of chain/carrier and secondly the type of cables to be fitted to the chain, followed by the layout of the cables in the chain. Most of the major chain manufactures have some documentation detailing how to choose and setup their chains to ensure the longest lifetime of both the chain and its contents. Following those guidelines to the letter would ensure lifetimes typically in the 10 of millions cycles range, but would also produce excessively wide chains that we could not easily fit into our applications.

Model Table

| Type | TL65 | TL95 | TL125 | TL180 | TL225 |

| Pitch | 65 | 95 | 125 | 180 | 225 |

| Bending radius(R) | 75. 90. 115. 125. 145. 185 | 115. 145. 200. 250. 300 | 200. 250. 300. 350. 470. 500. 575. 700. 750 | 250. 300. 350. 450. 490. 600. 650 | 350. 450. 600. 750 |

| Min/max Width | 70-350 | 120-450 | 120-550 | 200-650 | 250-1000 |

| Inner H | 44 | 70 | 96 | 144 | 200 |

| Length L | Customized by the user | ||||

| Max bore of support plate | 35 | 55 | 75 | 110 | 140 |

| Rectangular hole | 26 | 45 | 72 | ||

Structure Diagram

Application

The drag chains have already extensively used in digital-controlled machine tools, electronic equipment, machinery for stone industry, machinery for glass industry, machinery for doors and windows, moulding injectors, manipulators, lifting and transport equipment and automatic warehouses, etc.

Product detail pictures:

Related Product Guide:

Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for Best quality Electrical Drag Chain - TL250 Steel Energy Drag Chain – JINAO , The product will supply to all over the world, such as: Vietnam, Philippines, Berlin, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.