New Arrival China Chip Conveyor Type - Magnetic Type Chip Conveyor Equipment – JINAO

New Arrival China Chip Conveyor Type - Magnetic Type Chip Conveyor Equipment – JINAO Detail:

Magnetic chip conveyor utilizes the strong magnetic effect generated by the permanent magnet material to separate the powdery, granular and iron chips having a length of less than 100 mm, the debris in the cooling medium, and adsorbed on the working surface of the chip discharging machine. Delivered to the designated station. The machine can be widely used in CNC machining machines, combined machine tools, machining centers and other mechanical processing equipment and production lines for iron filings, and can be used for dry and warm processing of iron filings.

The device adopts a closed structure, uniform chip discharge, stable operation, low noise, and can be used for transportation and lifting of iron parts, and can be used as a primary filter in combination with a purifying device.

The Main Technical Parameters

| Style | Working width B | B1 | B2 | H(m) | H1 | H2 | H3/L1 | L(m) | a | kg/h | kw | l/min |

| SHYC150 | 150 | 220 | ≥300 | 0-3 | 130 175 204 | H1+≥30 (hypotenuse) | User-defined | 0.6-10 | 100 | 0.2-0.75 | 25 | |

| SHYC200 | 200 | 270 | ≥350 | 0-5 | 130 175 204 | 0.6-30 | 0° | 150 | 0.2-1.5 | 50 | ||

| SHYC250 | 250 | 320 | ≥400 | 0-10 | 130 175 204 | 30° | 200 | 0.2-1.5 | 100 | |||

| SHYC320 | 320 | 390 | ≥500 | 0-10 | 130 175 204 | 45° | 250 | 0.2-2.2 | 200 | |||

| SHYC400 | 400 | 470 | ≥600 | 0-10 | 130 175 204 | 60° | 300 | 300 | ||||

| SHYC500 | 500 | 570 | ≥700 | 0-10 | 130 175 204 | 75° | 400 | 400 | ||||

| SHYC600 | 600 | 670 | ≥800 | 0-10 | 130 175 204 | 90° | 500 | |||||

| Note: can be designed and manufactured according to customer’s required size | ||||||||||||

Application

The magnetic chip conveyor uses the magnetic force of the strong magnetic field generated by the permanent magnet material to adsorb the chips on the working magnetic plate of the chip conveyor, or remove the granular, powdery and iron with a length of ≤150 mm in oil and emulsion. The chips are adsorbed and separated, and transported to the designated chip removal location or chip collection box. It can handle powdery, granular and iron scraps and non-rolled scraps with a length of less than 100 mm, or separate the scraps in oil and emulsion, and transport them to the designated chip removal box.

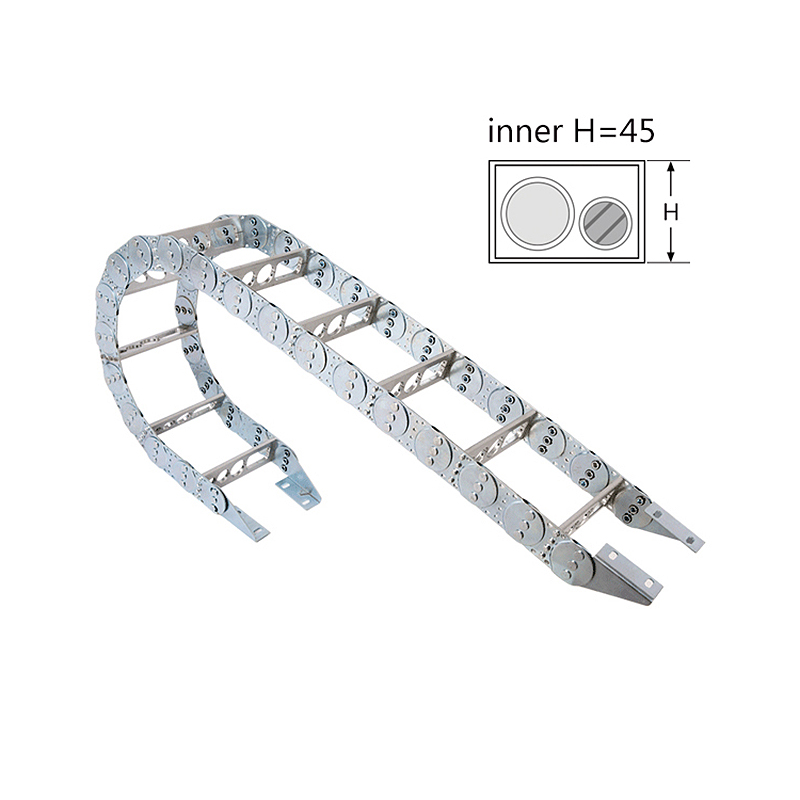

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for New Arrival China Chip Conveyor Type - Magnetic Type Chip Conveyor Equipment – JINAO , The product will supply to all over the world, such as: Ecuador, Netherlands, Melbourne, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.