Rapid Delivery for Cable Drag Chain Cps - TZ10 Openable Nylon Drag Chain – JINAO

Rapid Delivery for Cable Drag Chain Cps - TZ10 Openable Nylon Drag Chain – JINAO Detail:

Cable Drag Chain – The hoses & electrical cables connected to machinery parts in motion may get damaged as direct tension is applied on them; instead the use of Drag Chain eliminates this problem as the tension is applied on Drag Chain thus keeping the Cables & hoses intact & facilitating smooth movement.

Salient features include less weight, low noise, non-conductive, easy handling, non-corrosive, easy of assembly due to snap fitting, maintenance free, available in custom lengths, separators to segregate cables/hoses, can be used for side by side in case number of cables is more, increases cable/hoses life, modular design simplifies cable/hose maintenance.

The Cable Drag Chain Is assemblies of single units that are snap fitted to form chain to specific length.

Cable and hose carriers are flexible structures made of links that guide and organize moving cable and hose. Carriers enclose the cable or hose and move with them as they travel around machinery or other equipment, protecting them from wear. Cable and hose carriers are modular, so sections may be added or removed as needed without specialized tools. They’re used in many settings, including material handling, construction, and general mechanical engineering.

Model Table

| Model | Inner H×W | Outer HX W | Bending Radius | Pitch | H | A | Unsupported length | Style |

| TZ-10.10 | 10X10 | 15X17.5 | 28 | 20 | 10 | 10 | 1.5 | Whole |

| TZ-10.15 | 10X15 | 15X24 | 18 | 20 | 10 | 25 | 1.5 | |

| TZ-10.20 | 10X20 | 15X27.5 | 28 | 20 | 10 | 20 | 1.5 |

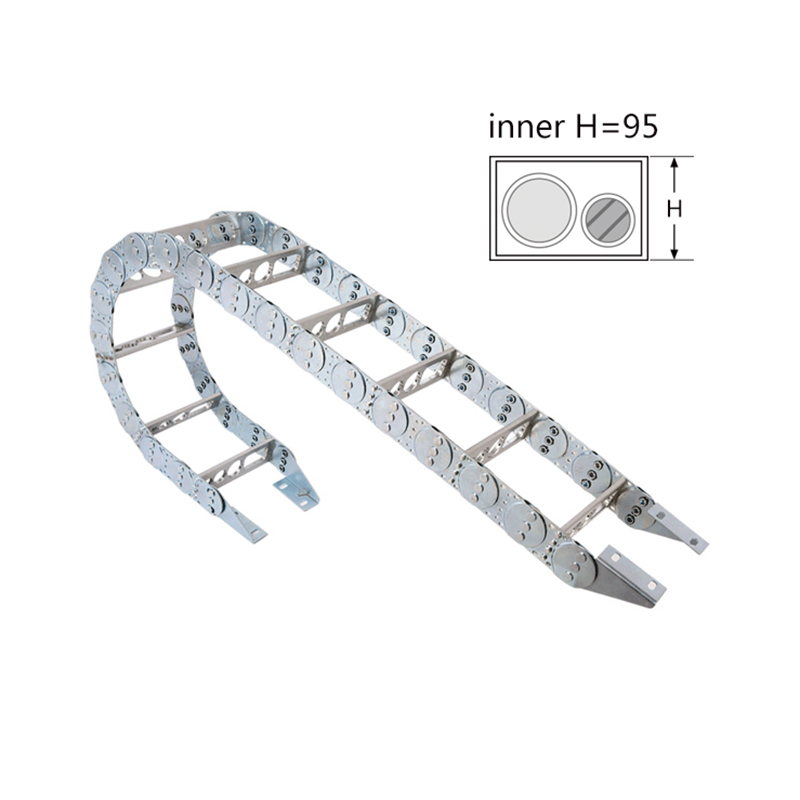

Structure Diagram

Application

Cable drag chains can be used in a variety of applications, wherever there are moving cables or hoses. there are so many applications include; machine tools, process and automation machinery, vehicle transporters, vehicle washing systems and cranes. Cable drag chains come in an extremely large variety of sizes.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Rapid Delivery for Cable Drag Chain Cps - TZ10 Openable Nylon Drag Chain – JINAO , The product will supply to all over the world, such as: Madras, Holland, Senegal, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.