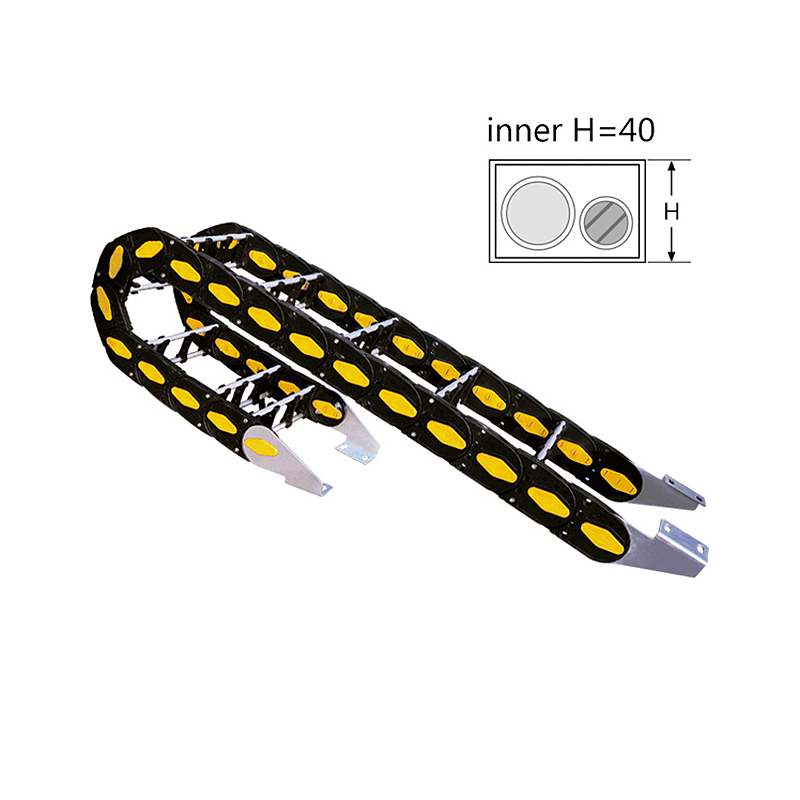

Reliable Supplier Flexible Plastic Cable Drag Chain - 40 Aluminum Rod Carrier Chain Cable Drag Chain – JINAO

Reliable Supplier Flexible Plastic Cable Drag Chain - 40 Aluminum Rod Carrier Chain Cable Drag Chain – JINAO Detail:

Salient features include less weight, low noise, non-conductive, easy handling, non-corrosive, easy of assembly due to snap fitting, maintenance free, available in custom lengths, separators to segregate cables/hoses, can be used for side by side in case number of cables is more, increases cable/hoses life, modular design simplifies cable/hose maintenance.

The Cable Drag Chain Is assemblies of single units that are snap fitted to form chain to specific length.

Cable and hose carriers are flexible structures made of links that guide and organize moving cable and hose. Carriers enclose the cable or hose and move with them as they travel around machinery or other equipment, protecting them from wear. Cable and hose carriers are modular, so sections may be added or removed as needed without specialized tools. They’re used in many settings, including material handling, construction, and general mechanical engineering.

Standard cable and hose carriers have an open design and are used in general purpose applications. Heavy-duty steel cable and hose carriers also have an open construction but are suitable for more demanding environments than standard carriers. Enclosed cable and hose carriers fully encase conductors to provide more protection from debris than open designs. Multiaxis cable and hose carriers turn and flex in any direction and are commonly used in robotics applications.

Model Table

|

Type |

Inner height |

inner width |

Outer H*W |

Style |

Bending radius(R) |

Pitch |

Unsupported length |

|

40 Aluminum rod type |

40 |

80-400 |

67*(A+27) |

Aluminum rod type |

75.100.125.150.200.225.250.300 |

70 |

4m |

Structure Diagram

Application

Aluminum cable chain successfully operated in aggressive chemical environment.

At the request of the customer, we complete the cable carrier system the fixing and guide systems in the form of bearing trays, brackets, rollers, etc.

Our advantage is the development of projects and supply assembled drag chains with cables inside.

Product detail pictures:

Related Product Guide:

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for Reliable Supplier Flexible Plastic Cable Drag Chain - 40 Aluminum Rod Carrier Chain Cable Drag Chain – JINAO , The product will supply to all over the world, such as: Romania, Luxembourg, Singapore, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!